Introduction

When it comes to drilling, down-the-hole hammer drilling is a game-changer. This innovative technique involves using a hammer to break the rock, making it ideal for deep and large diameter holes. But how does it differ from top hammer drilling? And what exactly is down-the-hole piling? Let's dive in and explore the exciting world of down-the-hole hammer drilling.

What is Down-the-Hole Hammer Drilling?

Down-the-hole (DTH) hammer drilling is a method of rock drilling that uses a pneumatic hammer to pulverize the rock at the bottom of the hole. This technique allows for faster and more efficient drilling in various types of rock formations, making it a popular choice for mining, construction, and exploration projects. In contrast to top hammer drilling, where the hammer is located above ground and transmits energy through a drill string to the bit at the bottom of the hole, DTH hammer drilling delivers impact directly to the bit. This results in less energy loss and more precise drilling, especially in hard rock formations.

The Difference Between Top Hammer and Down-the-Hole

Top hammer drilling, on the other hand, involves a smaller drill bit that is located at the top of the drill string. This method is typically used for smaller diameter holes and shallower depths. In contrast, DTH hammer drilling is capable of reaching greater depths and larger diameters due to its powerful pneumatic hammer.

Top hammer drilling is often chosen for its precision and efficiency in creating smaller holes for tasks such as anchoring, bolting, and small-scale construction projects. The smaller drill bit allows for more accurate placement and control, making it ideal for applications where precision is crucial. On the other hand, DTH hammer drilling's powerful pneumatic hammer makes it the go-to choice for larger scale projects such as mining, quarrying, and water well drilling. Its capability to reach greater depths and larger diameters makes it a versatile option for heavy-duty tasks that require significant drilling power.

What is Down-the-Hole Piling?

Down-the-hole piling refers to using DTH hammers for pile driving applications. By utilizing this technique, construction projects can achieve higher productivity and cost-effectiveness when compared to traditional pile driving methods.

By using DTH hammers for pile driving, construction projects can benefit from increased precision and accuracy in creating deep foundation piles. This method allows for better control over the depth and alignment of the piles, resulting in a more stable and reliable foundation for structures. Additionally, down-the-hole piling reduces the risk of damage to surrounding structures and minimizes disturbance to the environment, making it a more sustainable option for construction projects.

Understanding Down-the-Hole Hammer Drilling

Down-the-hole hammer drilling is a method of drilling rocks using a hammer that is located behind the drill bit. This allows the energy to be transferred directly to the drill bit, resulting in faster and more efficient drilling.

How Down-the-Hole Hammer Drilling Works

The down-the-hole hammer drilling process begins with the hammer being located behind the drill bit, which is then connected to the end of the drill string. When activated, the piston strikes the back of the drill bit, creating powerful blows that break apart rock formations.

Benefits of Down-the-Hole Hammer Drilling

One of the main benefits of down-the-hole hammer drilling is its ability to achieve higher penetration rates compared to other methods. Additionally, it provides better hole quality and requires less energy, making it a cost-effective and efficient choice for various drilling projects.

Applications of Down-the-Hole Hammer Drilling

Down-the-hole hammer drilling is commonly used in mining, construction, geothermal exploration, and water well drilling due to its ability to efficiently penetrate hard rock formations.

In addition to its use in mining, construction, geothermal exploration, and water well drilling, down-the-hole hammer drilling is also employed in the oil and gas industry for wellbore drilling. This method allows for faster and more efficient drilling through hard rock formations, reducing overall project timelines and costs. Furthermore, down-the-hole hammer drilling has become a preferred choice for environmental and geotechnical investigations due to its ability to provide accurate and reliable data on subsurface conditions.

The Advantages of TEAMWHOLE Down-the-Hole Hammer Drilling

When it comes to efficient DTH hammers and bits, TEAMWHOLE is a top player in the industry. Their DTH hammers and bits are designed for maximum productivity, offering high penetration rates and long service life. With cutting-edge technology and superior engineering, TEAMWHOLE's efficient DTH hammers and bits ensure that your drilling operations are smooth and effective.

TEAMWHOLE's Efficient DTH Hammers and Bits

TEAMWHOLE's DTH hammers and bits are engineered to deliver outstanding performance in down-the-hole hammer drilling. These tools are designed to withstand tough drilling conditions, providing excellent energy transfer for faster drilling speeds. Whether you're working on hard rock or abrasive formations, TEAMWHOLE's efficient DTH hammers and bits will get the job done with precision and reliability.

System Introduction to TEAMWHOLE's Large Diameter DTH Hammers

TEAMWHOLE offers a range of large diameter DTH hammers that are perfect for handling big drilling projects. These hammers feature innovative designs that optimize energy transfer, resulting in high impact power for deep hole drilling. With exceptional durability and consistent performance, TEAMWHOLE's large diameter DTH hammers are the go-to choice for demanding drilling applications.

Features of TEAMWHOLE's Down-the-Hole Hammer Drilling System

TEAMWHOLE's down-the-hole hammer drilling system is packed with features that make it stand out from the competition. From advanced air cycle designs to efficient valve systems, every component is meticulously crafted to ensure optimal performance and minimal downtime. With user-friendly maintenance and long-lasting components, TEAMWHOLE's down-the-hole hammer drilling system offers unmatched reliability for your drilling needs.

Comparing Top Hammer and Down-the-Hole Drilling

When it comes to top hammer drilling, one of the main advantages is its ability to drill straighter holes in hard rock formations. This method is also suitable for smaller hole diameters and shallow depths. However, it can be slower and less efficient compared to down-the-hole hammer drilling, especially when it comes to larger diameter holes and deeper drilling projects.

On the other hand, down-the-hole hammer drilling offers faster penetration rates and higher productivity, making it ideal for larger diameter holes and deeper drilling projects. It also provides better hole straightness in challenging rock formations. However, it may require more maintenance and has higher initial costs compared to top hammer drilling.

So which method is more suitable for your project? Consider factors such as the size and depth of the holes you need to drill, the type of rock formation you will be working with, as well as your budget and timeline. Ultimately, choosing between top hammer and down-the-hole drilling will depend on your specific project requirements.

In conclusion, both top hammer and down-the-hole drilling have their own set of advantages and limitations. Understanding the differences between these two methods will help you make an informed decision when planning your drilling projects. Whether you opt for the precision of top hammer or the efficiency of down-the-hole hammer drilling, selecting the right method will ensure successful outcomes for your project.

The Impact of Down-the-Hole Hammer Drilling on Different Industries

Down-the-Hole Hammer Drilling in Mining

Down-the-hole hammer drilling has revolutionized the mining industry, allowing for faster and more efficient extraction of minerals. This method is ideal for hard rock mining, as it delivers powerful and precise drilling, resulting in increased productivity and reduced operational costs. With its ability to reach greater depths, down-the-hole hammer drilling has become an indispensable tool for mining companies worldwide. Additionally, the precision of this drilling method minimizes waste and environmental impact, making it a more sustainable option for mineral extraction. Furthermore, the speed and efficiency of down-the-hole hammer drilling allow mining companies to quickly access new mineral deposits, giving them a competitive edge in the industry.

Down-the-Hole Hammer Drilling in Water Well Drilling

In the realm of water well drilling, down-the-hole hammer drilling offers unparalleled speed and accuracy in creating boreholes for water extraction. Its ability to penetrate various types of rock formations makes it a preferred choice for well construction, ensuring reliable access to clean and sustainable water sources. The efficiency of down-the-hole hammer drilling has significantly improved the process of well installation and maintenance.

Down-the-hole hammer drilling has revolutionized the water well drilling industry by providing faster and more accurate boreholes for water extraction. With its ability to penetrate various rock formations, this method ensures a reliable and sustainable source of clean water. The efficiency of down-the-hole hammer drilling has not only improved the process of well installation and maintenance but has also reduced the overall cost of water well construction, making it a cost-effective solution for communities and businesses in need of water access.

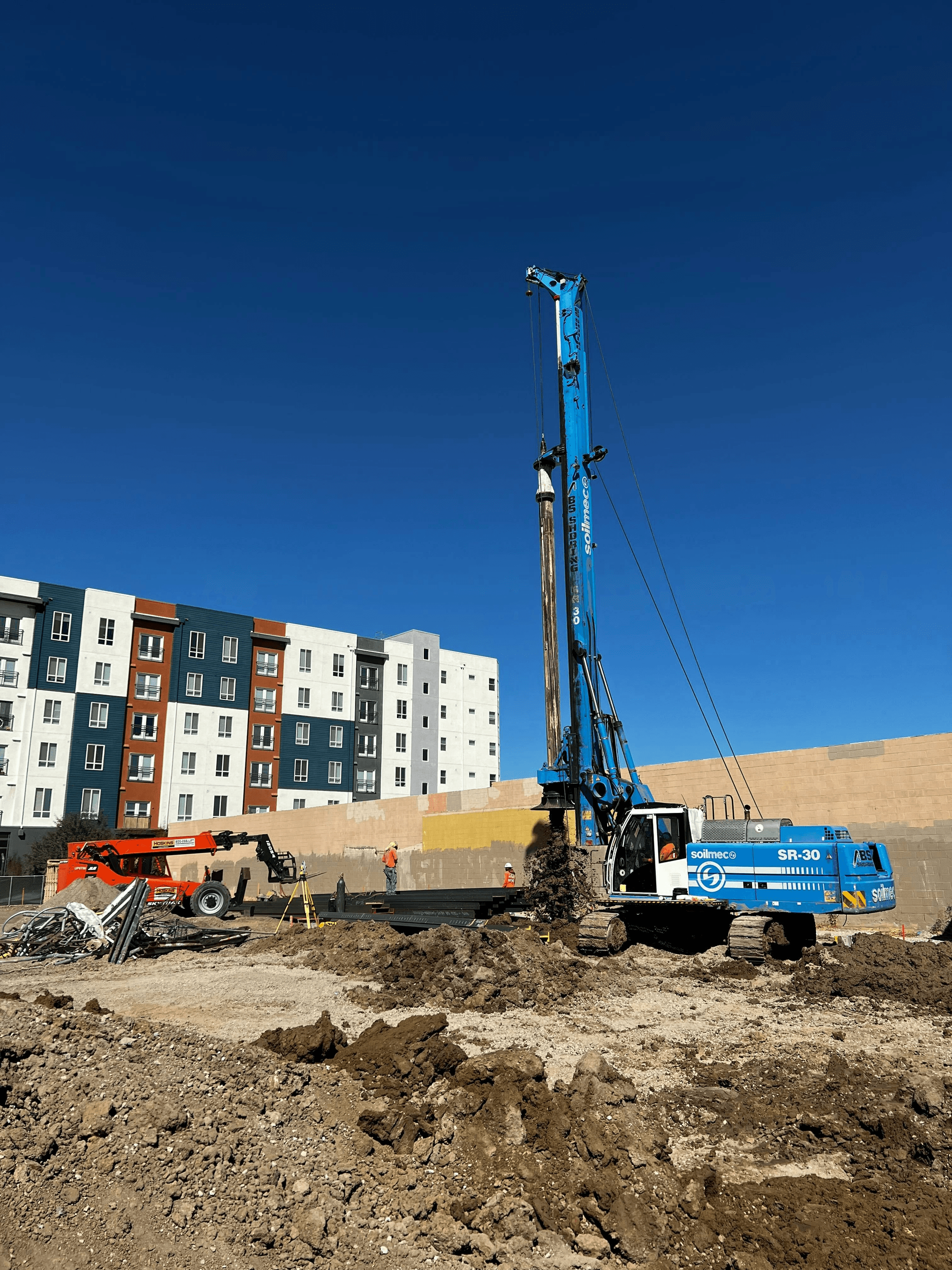

Down-the-Hole Hammer Drilling in Foundation Construction

When it comes to foundation construction, down-the-hole hammer drilling plays a crucial role in creating stable and durable structures. This method allows for precise placement of piles or anchors deep into the ground, ensuring strong foundations that can withstand heavy loads and environmental factors. The speed and accuracy of down-the-hole hammer drilling make it an invaluable asset in the construction industry, leading to safer and more resilient buildings.

Additionally, down-the-hole hammer drilling is highly versatile and can be used in various soil and rock conditions, making it a preferred choice for foundation construction in different geographical locations. This adaptability ensures that construction projects can proceed smoothly without the need for extensive equipment changes or adjustments. The ability to work efficiently in diverse environments further highlights the value of down-the-hole hammer drilling in creating strong and reliable foundations.

Conclusion

Choosing the Right Drilling Method for Your Project

When it comes to selecting the right drilling method for your project, it's essential to consider factors such as the type of rock or soil you'll be drilling into, the depth of the hole required, and the overall project budget. Down-the-hole hammer drilling is ideal for larger diameter holes and deeper depths, while top hammer drilling is better suited for smaller diameter holes and shallower depths. Understanding these differences will help you make an informed decision that aligns with your project's specific needs.

The Future of Down-the-Hole Hammer Drilling

As technology continues to advance, we can expect to see even more innovations in down-the-hole hammer drilling. With ongoing research and development, we anticipate improvements in efficiency, performance, and environmental impact. The future of down-the-hole hammer drilling looks promising, with potential advancements that will further streamline processes and enhance overall productivity across various industries.

Embracing the Efficiency of TEAMWHOLE's DTH Hammers

TEAMWHOLE's down-the-hole hammer drilling system offers unparalleled efficiency, reliability, and performance. Their efficient DTH hammers and bits are designed to maximize productivity while minimizing downtime and maintenance costs. With a focus on quality engineering and cutting-edge technology, TEAMWHOLE is at the forefront of delivering exceptional solutions for down-the-hole hammer drilling needs.